The main differences between the two materials are determined by their technological features of production. As a result of using better binders, MDF panels are more durable and reliable than particle boards. So, MDF has the following advantages compared to particleboard:

- Material safety. Particleboard panels use phenol-formaldehyde and urea-formaldehyde binder resins. As you know, formaldehyde belongs to the group of carcinogens dangerous to humans, which can even damage health in small amounts. In Western countries, the production of chipboard products is completely stopped due to these features. In turn, MDF panels are made of environmentally friendly materials.

- High moisture resistance. Particle boards, like MDF, are coated with a special water-repellent composition. Despite this, the protective effect does not last long, after which the particleboard begins to swell from moisture and deform. MDF boards are much longer protected from moisture.

- Carrying out paint work. The surface structure of chipboard panels is porous and uneven, therefore, for its painting, it is necessary to first clean the surface, putty the bumps, etc. MDF panels are available with the existing coating, which can have any appearance, depending on the wishes of the master.

Despite the obvious advantages, MDF wall panels also have negative properties compared to particleboard. So, one of the main properties is low resistance to high temperature. MDF boards begin to deform at temperatures beyond 700 degrees, and cracks and bubbles appear on the surface. High fire hazard is one of the most important drawbacks.

Knowing how MDF differs from chipboard, taking into account both advantages and disadvantages, we can conclude regarding the advisability of using these panels instead of chipboards.

Hallway and living room

With the help of MDF wall panels, you can beautifully decorate the hallway. The design of the elements used can be varied. Particularly popular are wood-like products.

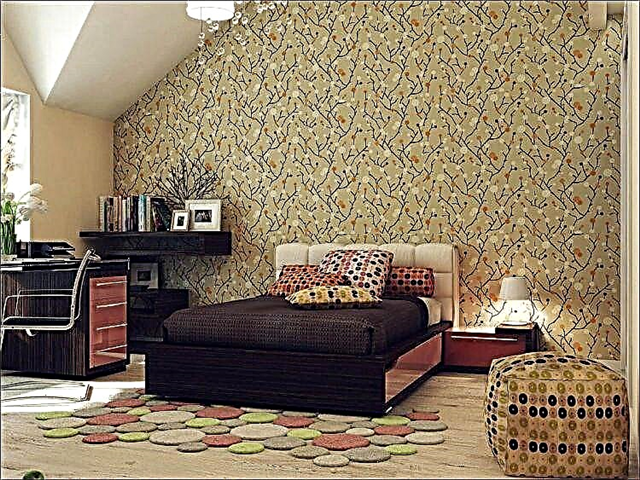

To design a living room, panels with various colors and patterns can be used. The choice depends on the overall stylistic design of the room. Check out the photos of the options.

Bedroom and bathroom

In the bedroom, MDF wall panels are used primarily for decorating the headboard. However, other options are possible.

Manufacturers allow the use of MDF wall panels for finishing bathrooms. Despite the moisture resistance of the material, direct contact with water should be avoided.

Wall panels mounted in the bathroom must be moisture resistant

Kitchen and loggia

In the kitchen, MDF boards are used not only for wall decoration, but also for the manufacture of furniture. They make the countertops and facades of kitchen sets.

MDF is suitable for interior decoration of the walls of the loggia and decoration of the balcony. Wall panels can not only beautifully design the base, but also insulate the walls.

Advantages and disadvantages

The main disadvantage of high-quality materials for decorating showers is their high cost. But, as mentioned earlier, a way out was found during the creation of MDF panels. The panels are really effective for bathrooms: they are affordable, durable, durable, practical, convenient and easy to install.

The material is primarily processed in a special way to the formation of fine crumbs. Then, by dry pressing under the influence of high temperature and pressure, it acquires the desired shape.

It is worth noting that the domestic market is characterized by stable demand for MDF panels.

They have a number of significant advantages:

- lightness and simplicity of installation, which can be done with your own hands (removal of old coatings and leveling are not required, installation can be done using improvised tools without the use of professional equipment, there is practically no dirt, dust, waste during operation),

- universality (suitable for decoration not only walls but also the ceiling),

- durability (with proper use of the finish of MDF to serve more than 10 years),

- strength,

- moisture resistance

- antiseptic properties (panels are treated with substances that protect against the formation of mold and fungi),

- easy care (you can clean dirt from the surface with a damp sponge),

- affordable price,

- ease of cutting

- various mounting options to the surface are possible,

- are excellent heat insulators,

- the raw materials from which the panels are made is environmentally friendly,

- represented by a fairly wide range.

In addition to all of the above, the decoration material in question can be combined with any other decoration materials. For example, many combine MDF panels with a coating of stone or tiles - this is one of the most attractive options in appearance. It is also possible to combine different finishes.

The resistance of MDF panels to the effects of high humidity allows them to be used also in bathrooms with a large area.

Despite the large number of positive aspects, negative aspects are also characteristic of MDF panels. However, you should not be afraid of this: this applies to all other finishing materials, but each of them has its own disadvantages. The correct approach to the installation and operation of such panels will help to avoid negative manifestations.

The disadvantages of MDF panels are usually include:

- low impact resistance

- it’s easy to damage the surface, such as scratches,

- insecurity in terms of fire safety.

So, MDF panels have high performance, despite the presence of certain disadvantages. But you need to maintain a serious attitude towards them, because if they are not treated correctly, they can really cause some problems. At the same time, exaggeration of the shortcomings is useless - the right approach will ensure getting rid of them, moreover, they may not appear at all.

In general, all indicators of the material do not require individual recommendations.

Beautiful examples

MDF wall products can be installed in a wide variety of rooms, from active halls and cafes to rooms of apartments or houses. For many builders, such a finishing material may be associated with “official” and boring decor, but in fact this is not so - thanks to the chic choice of colors and textures, such panels can create beautiful and stylish compositions. At the same time, in the interior decoration of rooms, products look good not only with imitation wood, but also with other natural materials

In addition, wall sheets are perfectly combined with various inserts, so you can get a stunning effect in the design.

When choosing panels for the design of a living room, it is important to consider what functions the room will perform and how many spatial zones it consists of. Most often, the walls of the living room are decorated with classic-style products.

They do this in such a way that they are a kind of continuation in the decor of the fireplace, doorways, stairs and other interior items. At the same time, it is recommended to alternate panels for light and dark wood or to combine two shades at the same time. For example, a drawing room looks original in which one wall is sheathed with light panels under an oak, and the other is dark under a wenge.

- In addition, in the rooms that combine the recreation area and the dining room, it is possible to make combined paneling horizontally. From below to half the wall will be placed material of a dark color, and from above - light. To hide the spaces between the transitions of the color scheme, it is recommended to install additional decor from a wooden plank. The walls, which are paneled vertically from floor to ceiling, also look interesting in living rooms. Due to the fact that the material attached to the base acquires a strip structure, the surface is striped, as a result of which the space visually expands.

- Laminated MDF products will become a real decoration for the kitchen. As a rule, a material with imitation of wood and natural stone is chosen for this type of room. With the right design, such panels will help to make the room modern and stylish, fill it with home coziness and comfort. Most often, veneered or laminated MDF boards are used for the kitchen - in their beauty and structure they are close to wood, therefore it is recommended to place them in the lunch area.

- In addition, MDF wall panels can completely displace ceramic tiles in the kitchen, as they have great superiority over it. The dining area, decorated with such panels, will take on an interesting look. The choice of material colors depends on the size of the room. For small kitchens, it is recommended to use light panels, and for spacious rooms you can apply a maximum of imagination and combine MDF sheets under a tree with panels of a different texture. Thus, we get an unusual interior that allows you to visually divide the kitchen into several zones.

- Looks good in the kitchen and partitions, lined with wall panels. In this case, it is best to prefer sheets of expensive veneer or tiles covered with varnish. Unusual look on such partitions and products with photo printing.

- A common problem in the design of the kitchen is the difficulty in choosing a finishing material for covering the working area, which is located between the lower and upper rows of furniture. Thanks to moisture-resistant MDF panels, these places can be turned into a real work of art. To do this, tiles with a pattern are selected and they are additionally covered with glass. Thus, it turns out a beautiful apron that harmoniously fits into any style.

- MDF panels are also widely used in the design of hallways. Since this room is always furnished and characterized by small size, then for the sheathing of its walls you need to choose the right shape, texture and color scheme of the finishing material. It is advisable to give preference to light shades - they will hide the lack of room space and visually expand the boundaries of its space.

The soft texture and unusual shades of the panels will not only radically change the look of the room, but also give it a harmonious image. Due to the fact that the material is characterized by high moisture resistance, it can be sheathed walls in any place: near the shower, between the hanging furniture and near the washbasin. In addition, the products perform zoning of the room and add chic to the interior.

See how to install MDF panels on the wall.

No. 1. Production Features and Benefits

For the production of MDF panels used wood chips that mix with urea resins. Plates are formed from this homogeneous mass, which are processed by dry pressing under the influence of high temperature and pressure. As a result, a dense plate is formed, which at the subsequent stages of production is given the necessary decorative properties.

Rapid distribution of material dictated many of its advantages:

- beautiful appearance and a wide selection,

- ease of installation and maintenance,

- panels can be installed in any direction

- there is no need to carefully prepare the original surface, because the panels will hide all minor defects in the walls or ceiling,

- since the panels are mounted on the crate, between them and the original surface there is a space that can be used for laying cables or for additional sound insulation.

No. 2. Why is MDF better than chipboard?

Often, MDF boards are compared with products made of chipboard: they are made of wood chips, and they look very similar. The difference is in the type of binder used for the chips: in the production of MDF, better materials are used, therefore, the plates are more durable and safer.

The main advantages of MDF boards compared to particleboard:

- health safety. Phenol-formaldehyde resins are used as a binder in particleboard. Material in the end can emit formaldehyde, which even in small amounts causes serious damage to human health. That is why Europe has long abandoned the production of particleboard. MDF panels are completely harmless to health, therefore they are used even in children's rooms,

- protection against moisture. Particleboard is covered with a water-repellent composition, but the protective properties are not enough for a short time, after which the boards can swell under the influence of moisture. MDF panels are much more resistant to moisture.

Nevertheless, it is worth noting that MDF panels are more sensitive to high temperatures than particle boards, and their main drawback is the high fire hazard.

Number 3. Types of MDF panels depending on the production method

Although the principle of production of MDF panels remains general, some nuances can be used that affect some properties of the material. Depending on the technological features of production, these types of panels are distinguished:

- fully pressed. The most common and common option. Wood pulp is pressed under high temperature and pressure, and as a result, a slab with smooth surfaces comes out

- laminated. They are made in the same way as fully-pressed, but with one difference - at the final stage, the front panel is covered with a thin polymer film, which becomes additional protection against moisture and mechanical damage. The film can be absolutely any color,

- moisture resistant. For this kind of boards, the highest quality wood is used. Sawdust together with a binder can be processed for a longer time at a high temperature, due to which more durable and resistant to negative influences boards are obtained. They can be used for lining bathrooms and balconies.

Number 4. MDF panels according to the method of designing the front part

To give the material an attractive appearance, the front part is made out in one of the following ways:

- veneering. It allows you to achieve a chic appearance that completely imitates natural wood, although it is difficult to call it an imitation, because a thin layer of real wood is used to clad the panel, the thickness of which is no more than 3 mm. This is enough to convey the original texture and color of the tree,

- polymer film lamination, which can convey any pattern: abstract patterns, structure of wood, stone, etc.,

- staining. A layer of paint covers the rough surface of the panel, which acquires a certain shade and a matte or glossy surface depending on the type of paint.

The choice of a particular option depends on personal preferences and design features of the room.

Depending on the features of the front surface of the MDF panel is also divided into:

- flat

- embossed.

No. 5. MDF panel size

Each manufacturer produces MDF panels with the parameters that they consider necessary - there are no unified requirements yet. The length and width of the panels varies widely, the thickness, as a rule, is 5-25 mm.

Depending on the shape and size of the panels, they are usually divided into:

- rack type. These are long boards 11-29 cm wide and 2-4 m long.They may come in handy when decorating spacious rooms in attempts to imitate natural wood cladding,

- typesetting panels. These are square plates with a side of 29-95 cm. You can use tiles of the same color and texture, you can combine different ones - in any case, you can achieve an interesting decorative effect,

- sheet panels. The sizes of such sheets are from 1.2 to 2.5 m. Often find application in lining large bathrooms.

SWISS KRONO GROUP

Once in 1897, it was a small sawmill located in Austria. Today company group includes a lot of factories located Worldwide, its products are in demand all over the world, and the name of the company has become a kind of quality mark. The company’s factory was also opened in Russia in 2002which today is well known as Kronostar. This enterprise is today considered the country's largest producer of wood-based panels.

In the country, Kronostar MDF boards are very popular, because they have European quality and domestic prices. The company offers a huge selection of such panels, they have many advantages, are used for wall cladding and, if desired, ceilings, can be laid horizontally, vertically or at an angle.

P&M Kaindl

This Austrian company with more than a century of history today is considered the world leader in the production of MDF panels. Here they use only the highest quality raw materials, modern high-tech equipment and constantly introduce innovations, as a result of which the products constantly receive prestigious awards. The company specializes in the production of laminate and MDF panels, each time striking with new developments. Products are exported all over the world; it is also represented in Russia.

Sonae industries

Not much behind the giant in terms of sales and portuguese company, whose plants are now located in 12 countries. The company has existed since 1959, at first it produced plastic products, then it produced chipboard, and since 1990 it has been manufacturing MDF panels. Today, the company is one of the three largest manufacturers of MDF panels in the world. Such high results were achieved thanks to a strict approach to quality control, continuous improvement of technology and the expansion of the range.

KASTAMONU

The company has been operating since 1969 and today combines production in Turkey, Romania, Bosnia and Herzegovinawas recently opened factory in RussiaTherefore, the company's products are actively entering the domestic market and are notable for a rather low price. High production speeds allowed the company to enter the five of the best woodworking companies in Europe. The plants of the enterprise use modern technology, new technologies are constantly being introduced. The company's assortment includes MDF panels with the most diverse coatings and sizes, and there are so many decor options that everyone will definitely find an option for themselves.

CJSC Plitspichprom

A large domestic enterprise, which includes several plants. The production of MDF panels is carried out by Lesplitinvest OJSC, which uses the best and most advanced European technologies adapted to domestic operating conditions. Today, 35 types of various panels are produced here, and equipment of Italian, German and Swiss production is used. The assortment includes veneered, painted and laminated panels, there are a lot of design options. Prices are different: there are budget options, and quite expensive.

"Zheshart Plywood Mill"

The company has been operating since 1946, and today it is one of the main domestic manufacturers of MDF boards. Products are used not only in Russia, but are also actively exported to neighboring countries. Modern equipment is used, new progressive technologies are constantly being introduced, production volumes are increasing.

LLC "Master and K"

For several years this group of companies has been a leader in the domestic market for the production of MDF panels. The manufacturer appeared in 1995, began with the manufacture of chipboard, and today its range is very extensive and also includes MDF panels. They are presented in several collections, which are constantly updated and updated with new types, so the buyer will certainly be able to find an option with the necessary technical characteristics and design.

Latat

Another responsible manufacturer of full-cycle MDF boards. The company itself produces logging, it itself produces low-toxic resins used as a binder, and it produces plates using modern German equipment. The company's specialists control all stages of production, which allows us to achieve high quality products.

Which is better: chipboard, MDF or chipboard?

Since furniture is made not only from MDF, before considering the rating we compare briefly other materials that are similar in structure but have a more affordable cost. This will help you decide exactly which is better and understand what the money is given for.

+ LARGE CHOICE OF COLORS

+ WELL KEEP THE SCREWS

+ MORE RESISTANT TO MOISTURE

+ THE MOST SECURE FORMALDEHYDE CONTENT

+ WELL PROCESSED BY MILLER, JOB JOB

-SORTING FROM TEMPERATURE 80-100 DEGREES

+ GLUES WITH WOOD, PLASTIC

-BAD KEEPING TAPES

-DO NOT hammer a nail

-NO COLOR OPTIONS

-NON-ATTRACTIVE VIEW (ONLY FOR INTERNAL PARTITIONS)

+ BEAUTIFUL VIEW OF LAMINATED SURFACE

+ VARIETY OF FLOWERS AND STRUCTURE

+ SLOW SELECTION OF FORMALDEHYDES

+ PROTECTED FROM MOISTURE

-PROOF INTERNAL MAJOR LAYER

Rating of the best manufacturers of MDF panels

| Nomination | a place | Name of product | rating |

| Rating of the best manufacturers of MDF panels | 1 | Swisskrono | 5.0 |

| 2 | Union | 4.9 | |

| 3 | Albico | 4.8 | |

| 4 | Finitura | 4.7 | |

| 5 | Eurostar | 4.6 | |

| 6 | Avic | 4.5 | |

| 7 | Nevsky laminate | 4.4 |

Understanding the advantages of MDF over other materials, we consider the rating of the best manufacturers. This will help to find quality products for specific tasks.

Swisskrono

The first place in the ranking is held by a Swiss manufacturer, whose products are especially popular in Poland, Russia and Ukraine. In total, MDF brand panels are sold in 75 countries. The company has been developing and producing MDF for over 50 years. All production is conducted on our own industrial premises. There are lines for pressing, introducing a paper decorative layer, laminating, cutting. Resin and glue are also made here, so all products are of excellent quality. Customers in the reviews like the fact that the MDF panels from this manufacturer do not fade under the influence of ultraviolet radiation.

We rated the manufacturer as the best because of the large selection of dense MDF panels made using postforming technology. These are chipboards with a height of 20-30 mm, used for countertops. They have a particularly strong top layer, resistant to abrasion and high temperature. This surface is easy to keep clean.

Disadvantages

- high price,

- the surface is scratched with sharp objects

- you can leave a deep stain on the panel from ink or blood,

- the material is not suitable for polishing agents.

In second place is the domestic manufacturer, which produces both individual MDF panels and ready-made headsets. The company strives to maintain high quality in order to compete with European brands. The most famous product lines are Alleanza Room and Alleanza Kitchen, which feature MDF boards for living rooms and rooms with high humidity. Buyers in the reviews like that you can immediately buy the necessary trifle from the manufacturer, which comes in handy in the manufacture of headsets. High quality products are obliged to produce on German equipment KOCH, installed in 2012 and which has no analogues in Russia.

We have identified this manufacturer as the best in the rating, because it produces special MDF panels for wall decoration. These are strong plates that do not require additional processing. There is a wide selection of color options. The surface is protected from mold and mildew. It is worth paying attention to the MDF wall panels of this manufacturer when decorating various rooms (offices, cafes, restaurants, bars).

Albico

The third place in the ranking is occupied by a relatively young Belarusian manufacturer, which has been present on the market for only 5 years. Albico has already managed to take part in 19 international exhibitions and received a diploma for applying the latest technologies in production. The production of MDF panels is carried out on the Italian equipment "Orma". The manufacturer is trying to ensure that the product meets the E1 class for formaldehyde emissions, and its amount does not exceed 10 mg per 100 g of material. The company offers customers several MDF lines: Sp-lida, Master Gloss, standard Sp and Pl series. For lovers of special finishes there is a series of VIP-decor.

Our experts liked the manufacturer's special line with 3D panels. For its release, MDF is used, 4 mm thick, which is pressed in a matrix. This allows you to give the material a different embossed shape (branches, leaves, weaving, bark beetle, etc.). Also, users in the reviews like a wide variety of glossy panels with fascinating prints covered with laminate (for example, glasses with cherries and ice on a black background, or blooming sakura).

Finitura

Our rating is continued by a domestic manufacturer engaged in the manufacture of MDF since 1994. Now the range of the company includes 350 types of various panels. The output focuses on four lines: 3D panels with a laminated top, 3D panels for painting, 2D boards with fine wood finishes and 2D for painting. Sheets can be painted in any color according to the RAL table. As a decor, the company offers interesting solutions from MDF panels, for example, a large wall map of the world that will look spectacular in the lobby or office.

The manufacturer was included in the rating of the best due to the presence of unique MDF panels coated on the outside with natural veneer. Thanks to this, the top layer looks even more attractive and is able to tolerate increased temperature and mechanical stresses. The company also equips the panels with connecting grooves, which simplifies installation. Customers in reviews like the ability to assemble MDF with locks both vertically and horizontally.

Eurostar

The fifth place ranking is the company Eurostar. The manufacturer is known in Russia and neighboring countries. The catalog contains 11 options for colors of MDF, divided into groups: glossy light plates "Savannah", darker glossy panels "Oak", "Golden Velvet" and "Maple". There is a particularly dark series "Mahogany." Customer reviews like walnut veneered MDF. A feature of production is the release of plates with a thickness of only 7 mm. Despite the small assortment, the products are in high demand, since they are sold at a better price than the above listed participants.

In our opinion, the manufacturer deserves a place in the TOP-7 based on the manufacture of wall MDF with a width of 250 mm. Other companies produce panels of 195-200 mm. The increased dimensions are practical for cladding a large wall area or making cabinet furniture with fewer joints.

Nevsky laminate

Our rating is completed by a manufacturer from the Leningrad Region, whose factory is located in the village of Nevskaya Dubrovka. The company was founded in 1998 and uses hardwood (alder, aspen, birch) to produce MDF. For the production of panels involved German equipment. Designers closely monitor fashion trends in the world of finishes and try to keep up with leading brands. Consumers like that not only MDF boards can be purchased here, but also complex solutions - this saves time during subsequent furniture production or wall decoration. Plates are presented in the catalog by the Alternative line and are glossy, matte, with fine embossing. There are options that simulate metal (aluminum, copper, etc.).

The manufacturer is listed in the rating due to the presence in the catalog of special types of MDF, such as “Fireproof” and “Moistureproof”. The panels are colored red and green, respectively. This expands the scope of use of sheets in the decoration of rooms with high humidity or rooms, which are subject to higher fire safety requirements.

How to sheathe MDF panels - installation features

There are 2 main ways of fixing MDF panels to the wall:

- frame using a wooden crate or galvanized profile, which is used in cases where it is necessary to hide surface defects or engineering communications passing over walls,

- glue, which is used when installing MDF panels directly on smooth, prepared surfaces.

Each of these methods has its pros and cons. Glue is simple in execution, since it does not require preliminary placement of the frame and for installation you will need glue on wood or “liquid nails” and accuracy. However, for such placement of MDF panels, the walls should be prepared perfectly - they are aligned with maximum accuracy and completely cleaned of dust.

In order to carry out wall sheathing of MDF panels with the frame method, you may need the following tools: building glue or “liquid nails”, a plumb line, tape measure, level, a drill with a nozzle for wrapping screws, self-tapping screws, a screwdriver, self-extinguishing corrugation (if it is planned to place the carriage under the panels ), a metal bench square, a jigsaw or circular saw, MDF finishing panels for walls and horizontal profiles - the upper one (it can be ceiling or decorative for the upper border of the panels) and a plinth.

Since the length of MDF panels varies from 2400 to 3700 mm, it may be necessary to shorten them - this can be done independently using a jigsaw or circular saw or clarify the provision of a similar service from the seller.

Panel Mounting Steps

- Wall preparation. As mentioned earlier, the skeleton method does not require serious surface preparation, however, it is recommended to remove the old coating, for example, wallpaper, and cover the surface with a primer layer - this can prevent the formation of mold and mildew. Sound and heat insulation, if you plan it, is also placed at this stage (the insulation is fixed with any suitable adhesive).

- If wiring elements pass along the wall, they should be removed into cable channels or tubes from the corrugation.

- Placement of the crate, which can be made of galvanized panels or wooden blocks. The cross-section of the lathing should not be taken more than 20x40 mm, galvanized profiles due to some elasticity will be more acceptable for use in cases where the unevenness of the walls is significant.

Vertical profiles or bars of the required height are placed in the butt corners and next to the openings. If the wall is very long (more than 5 m), then you can make an additional vertical support in the center. The optimum distance between the supports for large rooms is 3 m. Vertical supports can be attached to the wall using self-tapping screws or suspensions.

We place the horizontal profiles of the required length on top of the vertical ones, starting from the bottom, practically from the floor itself, upwards in increments of 60 cm. Fastening on self-tapping screws.

- proceed to the installation of MDF panels. To place them on the frame, it is advisable to use clippers (they can be bought with panels, after consulting with the seller first).It is possible to use “liquid nails” instead of clippers, but during operation, due to the properties of the adhesive base, slight unevenness of the panel canvas may occur due to its relatively large area,

- we decorate the upper and lower borders of MDF panels with corners - they are simply glued using "liquid nails" or any glue for wood. MDF corners are quite flexible and can also be used for arched openings.

Scope of application

MDF panels are widely used for interior decoration. They finish floors and ceilings, make furniture from them and even transform the front doors. Such popularity is not accidental, because MDF boards can not only hide the unevenness of the walls, but also refine the interior as soon as possible and without unnecessary dirt. They can be mounted in any direction, it is convenient to “hide” wires and communications behind them. In terms of cleanliness, it is enough to wipe their surface, taking a damp cloth, while chemicals are not used.

MDF wall plates can be slatted (long and narrow), resembling a wooden lining. Tiled rectangular or square are similar to tiled plates, and sheet are wide smooth sheets. Due to the variety of shapes, you can modify the room by visually narrowing or expanding the room.

Installation of MDF sheets has its own characteristics, depending on the application.

- Due to uneven walls, panels are often mounted by attaching to aluminum profiles. If the walls are even, it is permissible to use the glue method. The glue should be thick and retain its plastic properties after drying, which will not allow the plates to deform or shrink.

- If you plan to decor the ceiling, the panels for it should be lightweight and easy to mount. The optimal solution will be the use of slat panels, the connecting elements of which are used liquid nails, a special adhesive solution or a construction stapler.

- The material is adjusted in length with a jigsaw or circular saw, and you can fix it alone. But for the installation of tiled or sheet MDF, you will need at least one assistant, which is not always convenient.

- Dense moisture-proof sheet panels are laid on the floor. If the sheets are laid on the rough floor, it is worth using plates whose thickness exceeds five millimeters. If the installation is done on logs, you should choose MDF from ten millimeters thick.

- In any case, before work, the base should be leveled and cleaned, and then the boards “laid apart” laid. The gap between the panels from the walls is 2–4 mm, and the distance between the panels themselves is 2–3 mm. Fasteners should be installed along the perimeter of panels in increments of 10-15 centimeters. Then proceed to grinding surfaces and puttying the joints, and only then to painting. The base of MDF can be used both under the laminate and under any flexible finishing material.

The design of the front side of MDF panels is also diverse. In addition to the usual flat products obtained during the pressing process, there are plates with a raised surface. The volumetric pattern obtained as a result of stamps, stickers or milling looks original, but gets dirty quickly, and you will have to wipe such panels much more often.

On top of the decorative films, transparent, glossy or matte polymer coatings are glued to the laminated boards to protect the panels from mechanical damage. Veneered front sides of the plates reproduce a natural woody pattern, and matte or glossy shades of painted surfaces will become a stylish decoration of the interior.

If you want to realize any unusual design idea, you should pay attention to the panel with a smooth, unprocessed surface. At home, you can clean it yourself, putty it, close the pores, smooth out irregularities, and then primer and paint it with the right color

MDF is “afraid” of water, but the bathroom or kitchen, loggia or veranda can be finished with moisture-resistant MDF panels, protected by a laminating layer on the outside and inside. It is only necessary to ensure that they are protected from direct contact with water.

Types of MDF panels and features of their use

There are several basic principles for the classification of decorative MDF panels, and we will consider their main types, characteristics and features of use.

Classification of MDF decorative panels by production method:

- All-pressed panels have medium density, their distinguishing feature is a smooth surface on both sides, which is not typical for MDF boards of other types. They are environmentally friendly, aesthetic, hygienic, have great moisture resistance and are mainly used for furniture production. The method of their production is based on the pressing of wood pulp using thermal exposure.

- Laminated MDF panels for walls are produced using the same technology as fully pressed, but at the final stage of production, the front side of each panel is covered with a thin transparent film that protects the surface from moisture, mechanical stress and gives the panel the look and beauty of real wood. Lamination can also be done in a wide range of colors, which allows you to choose the MDF panel in the exact range that is needed.

- Moisture-resistant MDF panels for walls are made of a higher density material compared to solid-pressed and laminated panels. The wood fibers used for the manufacture of this type of decorative MDF panels are of exceptional quality, their connection occurs under prolonged exposure to high temperature. The placement of moisture-resistant MDF panels is optimal for the kitchen, bathroom and rooms with high humidity, since in addition to low hygroscopicity, they also have good soundproofing qualities, high strength and pronounced ergonomic properties.

Classification by physical characteristics (size and shape):

- Slatted MDF panels are the most common and easy-to-install type that looks externally lining. The sizes of battens MDF panels for walls vary from 148 to 300 mm in width and from 2400 to 3600 mm in length, so you can choose the optimal size for each type of room. during installation, the rack panels are interconnected using lateral grooves and are fixed along the upper and lower parts using horizontal rails.

- Tiled MDF panels are a bit like tile, but they are larger in relation to it. The principle of mounting tiled MDF panels is the same as that of rack.

- Sheet MDF panels for walls are large decorative sheets on which a print or ornament is applied. They can be of various sizes and combined depending on the decor.

Classification by the method of decorative processing of the front part of the panel:

- Veneered MDF panels for walls, on which the surface resembles real wood as much as possible in color and texture. For such an imitation, a thin layer of veneer (wood sheets less than 3 mm thick) of real wood - ash, beech, mahogany - is glued onto the base of the MDF panel with a thin layer.

- Glossy MDF panels look stylish, respectable and as if highlighted from the inside. A similar effect is achieved by lamination with a high-gloss transparent film.

- Painted MDF panels are the most common in the furniture industry. The effect of deep color is achieved by applying special paint to the panel, which, spreading over the panel canvas, smoothes out all irregularities. Painted panels can be matte, glossy (using lamination) or have a “mother of pearl effect” - shimmer with shades of color depending on the lighting and viewing angle.

- 3d MDF panels for walls is a new trend in the production of MDF panels, with the help of which panels can give a certain relief, visually age the material, embed golden or silver glare in the texture of the picture, place a three-dimensional picture and even a photo, finishing and wall paneling. This result can be achieved by staining in many colors (if we are talking about relief), making an imitation of the surface under the skin, marble, silk with further lamination or by giving the veneered or painted surface a light glow effect.

Below is a photo of 3D mdf panels: a chic surface, isn't it?

Choosing MDF wall panels: general recommendations

To make the right choice:

- consider the purpose of the finish. Thin MDF panels having a thickness of less than 12 mm perform an exclusively decorative function. With their help, you can beautifully decorate the walls. Thicker products have good heat and sound insulation characteristics,

- make sure that there are certificates of conformity. It should reflect information on the composition of the material. In particular, the presence of formaldehyde and a toxic resin that is harmful to human health is unacceptable,

- Check all MDF panels from the purchased batch for external damage and defects. It is worth refusing to buy items that have cracks, bumps or other damage. Even if they are sold at a significant discount,

- make sure the uniformity of colors and uniformity of the formed layer. The presence of irregularities indicates a poor quality finishing material.

The choice of MDF wall plates should be taken with all responsibility

Features and dimensions of MDF

MDF, which is used in the manufacture of furniture, is created from sawdust, which are pre-pressed well, and then glued using a special substance - lignin. All components are environmentally friendly, therefore, products from the plates are safe for use in the children's room.

Due to the specific production process, a material is obtained that has good strength and other advantages:

- From it you can make high quality furniture,

- The structure of the material is homogeneous, it does not have any protruding fractions,

- Environmental friendliness and safety for the human body,

- Good moisture resistance, allowing the use of stoves in the kitchen or in the bathroom,

- Resistance to deformation,

- A wide palette of shades allows you to choose elements of a suitable color or texture.

The disadvantages include the fact that furniture made of veneered MDF has a higher cost compared to structures made of chipboard or plastic. If you act on it with significant mechanical loads, then cracks or dents may appear. Also, MDF is a highly flammable material, therefore it is not allowed to use it to create products that will be located next to an open flame.

Sheet sizes are standardly equal:

- If the thickness varies from 3 to 14 mm, then the area of the plates will be 2070x2800 mm or 2070x2620 mm,

- With a thickness ranging from 16 to 24 mm, the sheet has a size of 2070x2800 mm,

- The thickest plates, reaching a thickness of 38 mm, have a size of 2700x2800 mm.

The most popular are MDF panels 2070x2800 mm. When creating complicated moisture-resistant sheets, it is possible to produce mainly sheets of 1220x2440 mm.

Forms and methods of processing material

What is MDF in furniture? The decoding of this designation is a finely divided fraction obtained from small wastes of the woodworking industry. The production procedure involves the formation of a special mass of chips and glue. From it, plates of different thicknesses, areas and shapes are formed. If necessary, the desired relief can be made, which is especially important for creating unique furniture equipped with bent and elegant facades.

Panels, countertops, plinths, platbands or other products necessary for creating furniture, but also for decorating a room, are made of this material. Particularly popular are MDF furniture profiles that complete any decoration.

Furniture MDF panels have a fine-fibered structure, so a lot of dust is generated during their processing or milling. Due to the ease of cutting, you can independently create unique carved structures. Simplicity of processing allows using panels to create cabinet, built-in or modular furniture. When using CNC machines, you can even make curly images.

To improve the appearance and quality of furniture, different processing or decoration methods are used.

| Processing method | Its features |

| Lamination | From the outside, the panel is covered with a special PVC film, which is glued under high pressure. Due to this treatment, a matte or glossy surface is obtained. It can imitate various expensive materials, as well as be made in a variety of shades. The resulting coating is durable, resistant to sunlight and chemicals, high hygiene and easy to care for. |

| Veneering | The veneer may adhere to one or two sides of the board. To create it, valuable wood species are used, therefore, outwardly expensive furniture is obtained. When using veneer, the price of structures increases significantly. Due to this treatment, moisture-resistant panels are obtained that are resistant to warping and drying. |

| For painting | Such panels are fully extruded and have an unpainted surface. In this case, customers can decide for themselves what color and quality paint suits them best. Painting is carried out manually or using a special tool. |

There are many decors for such panels, which are selected by the users themselves.

The main varieties of MDF products include:

- Decorative panels for walls - equipped with grooves and ridges, simplifying installation. They form wall coverings in different rooms. To fix the elements, you can use glue or create a frame. They are distinguished by ease of installation, beautiful views, good thermal insulation and sound insulation. But such decorative elements are easily destroyed by mechanical stress, easily ignite and have a high price,

- Moisture-proof panels - are considered universal products that are highly resistant to moisture. They are considered ideal for a bathroom or kitchen. Moreover, they are easy to process, durable and have good soundproofing parameters,

- Glossy canvases - these MDF furniture panels are most often used to create kitchen sets, cabinets or hallways. Due to the glossy finish they are distinguished by their exquisite appearance, and also fit well into different interior styles. Additionally, this coating is well protected from various mechanical influences. Guaranteed long life. To create a coating, polyester or primer can be used,

- Flexible panels - appeared on the market relatively recently, but quickly became popular. They can take any shape, therefore they are effectively used to create bent facades, arches and other structures. Flexible elements have smooth surfaces that can be painted or decorated in different ways. With the help of such a painted curved facade, you can improve the appearance of any room.

The thickness of the MDF can vary from 4 to 16 mm. The lower this indicator, the more simple the plates will be in processing. But the subtle elements are quite fragile.