Good day. Tell me, please, how long does it take for silicone sealant to completely dry in the bathroom?

In order to seal construction joints from moisture, to isolate joints in the bathroom, most often apply one-component silicone sealants. Thanks to the well-thought-out form of packaging and the correct consistency, it is very convenient to work with them. Silicone connects surfaces well and firmly and does not allow moisture to pass through. The only thing that needs to be studied before starting work is how much the silicone sealant for the bathroom dries.

In order to seal construction joints from moisture, to isolate joints in the bathroom, most often apply one-component silicone sealants. Thanks to the well-thought-out form of packaging and the correct consistency, it is very convenient to work with them. Silicone connects surfaces well and firmly and does not allow moisture to pass through. The only thing that needs to be studied before starting work is how much the silicone sealant for the bathroom dries.

Types of silicone based sealants

Silicone sealants come in two types: neutral and acid. Neutral (it is also called sanitary) - resistant to high temperatures, so it is often used to repair pipes of the heating system, in plumbing, during repairs in the kitchen and in the bathroom. It contains alcohol and ketoxime, which give it antifungal properties.

Acidic sealants also contain antifungal components. Often this is acetic acid. The main problem of acidic sealants is that they cannot be used on metal, marble and cement-containing surfaces. But he glues wood, plastic and ceramics perfectly. When hit on wooden surfaces, such a substance goes deep into the material and creates its additional protection.

Where is sealant used?

Silicone sealants are quite suitable for both indoor and outdoor use. It is especially good for installing plumbing. In addition, silicone is often used in the assembly of various metal and plastic parts, in mechanical engineering and machine tool industry.

At a construction site and repair activities, silicone sealant is useful in such cases:

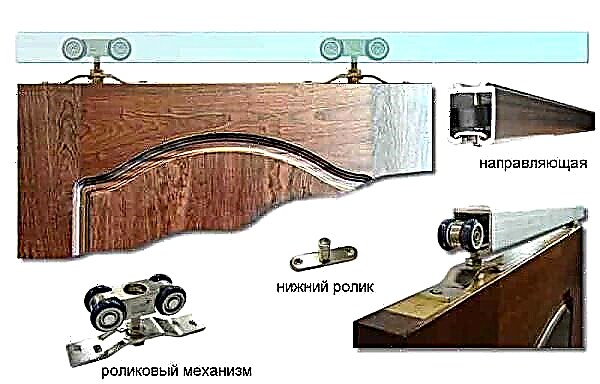

- For sealing gaps and joints when installing doors and windows.

- When gluing stone and ceramic tiles.

- In all plumbing installation work. In the bathroom, it will be used to process joints in the places where plumbing is attached, to attach mirrors, while working with water pipes and sewers, to seal the joints between the bathroom and the wall. It is also used to seal various cracks and joints of showers. Since the sealant makes moisture penetration impossible, all kinds of fungi will not appear.

- During installation work with a roof, all seams are processed with a sealant.

- When installing electrical wiring.

Using silicone sealant for repairs in the toilet

Using silicone sealant for repairs in the toiletHow long does the composition dry?

Gradually, we came to the main question: how long does silicone sealant dry? The period of its solidification very much depends on the scope and composition of the product itself.

Sealant polymerization time depending on type:

- Acid-based sealants require approximately 4-6 hours to dry.

- To completely dry the neutral silicone sealant, you need more time, about 24 hours. In addition, an important condition is the plus temperature - from 5 to 40 degrees.

Depending on the area of use, the drying time of the sealant may be as follows:

- If you apply this material abundantly enough, then its outer layer hardens and does not stick to your hands after 15 minutes. And in the inner layers at this time, the polymerization process is just starting. It passes at such a speed: every 2 mm of the inner layer hardens in 24 hours.

- If the room temperature is significantly increased, then the sealant will dry twice as fast. And if you carry out outdoor work in the cold season, then the sealant needs to be given more time to dry.

Tip: Read what is written on the package. Usually they indicate the drying time of the sealant under certain conditions.

Initial Drying and Curing Time

It is impossible to accurately predict the drying time, since in each case there are nuances associated with temperature, humidity in the room, layer thickness and other parameters. However, based on the experience of builders and repairmen, you can roughly say how much you need to wait before starting work with the frozen mass.

| Sealant Type | Application Feature | Application Conditions | Solidification time | The properties |

| Silicone |

There are transparent and colorless, do not stain, give an elastic seam. Resistant to moisture and temperature changes

How much silicone sealant dries

Since it is this variety that is universal and most used, we consider in more detail the working conditions with silicone sealant and the pour time, depending on these conditions.

General parameters affecting the speed at which the sanitary sealant dries:

- layer thickness. Each two millimeters of thickness is an additional day to the duration of full cure,

- room temperature. The normal range for using this material is 5 ... 40 degrees Celsius above zero. At temperatures above 25 degrees, the pour point is calculated by multiplying the average by a factor of 1.5 ... 2,

- humidity. Paradoxically, high humidity speeds up the ripening process. This is due to the fact that the polymerization of silicone is faster in the presence of water. Watering the sealant is not necessary! It is enough to create increased humidity in the room, for example, heat it to a temperature of 30 ... 35 degrees and put a container with heated water next to it.

Features of different types of silicone sealant

It is necessary to choose the material for sealing various joints and joints in the bathroom, taking into account the nature of the surface.

For metal surfaces, acidic silicone sealants should not be bought - metal corrosion will begin. Therefore, if it is necessary, for example, to protect the shower tray from moisture, it is better to choose the neutral option. At the same time, it is not universal, but sanitary - special substances have been added to it that interfere with the development of molds and pathogenic bacteria. It is worth considering that silicone sanitary sealant for a bathroom usually dries a little faster than universal varieties - the initial setting is not 25 ... 30, but 14 ... 20 minutes. Full solidification - from 48 hours to several days. You can start work in an hour or two after processing the seam.

Acidic (with acid polymerization) sealants are suitable for filling the joints between tiles, fragments of stone and wooden countertops, flooring. It is important at the same time to choose sanitary varieties for surfaces that often come in contact with moisture. You can specify how much acid-type sanitary silicone sealant dries directly on the package. It also indicates at what temperature it is possible to carry out installation work.

For acrylic countertops in the kitchen (acrylic stone) and bathtubs, it is better to use acrylic waterproof sealants. In this case, the reaction to external influences of the base material and suture will be the same. It is convenient that such an acrylic sealant dries faster than silicone, and after 12 hours it will be possible to use the installed equipment or continue its decoration. Interestingly, the seam can be painted in the right tone at the same time — this will not work with silicone sealants.

If it is necessary to hide the gaps in the room between the ceiling plinth and the ceiling / walls or to close the seam in another place that is not exposed to moisture and is not contaminated, it is easier to use a universal type of material. They are colorless (transparent), which is especially convenient for colored surfaces, to which it is difficult to choose the right shade, color and white. Given that ceilings are more often white, Moment products are well-suited. It is better to find out exactly how much the Moment sealant dries according to the data on the package, since the data may vary slightly depending on the working conditions and the specific type of composition.

Another interesting type of work in which waterproof silicone sealants are actively used is the repair or manufacture of aquariums. Glass is not affected by acidic bases, but the water in such an aquarium may not be suitable for fish. Therefore, it is better to glue the glass with colorless neutral compositions with increased resistance to dynamic loads. For this type of work, there are special sealants, it is undesirable to use universal options.

How long does silicone sealant of different brands dry for a bathroom and other rooms

Given the different popularity of domestic and foreign brands of sealant, we offer a small summary table. Basically, it will contain data on universal and sanitary varieties of the material, including information on how much the Moment silicone sealant dries.

| Sealant Type | The foundation | Mark | Initial setting time, minutes | Hardening time, hours |

| Universal |

Often these data can be obtained from indirect data - for example, the Ceresit company indicates that it is necessary to smooth the material in the seam no later than 6 ... 8 minutes from the time of application. Thus, after 10 minutes the initial setting is possible.

The exact time of complete solidification is not indicated by anyone! These data are so individual that it is unrealistic to install them without a tolerance of 3 ... 12 hours.

General recommendations

Given that information can only be obtained from the data on the product packaging, you should focus on:

- the base setting time, to which you can smooth or align the seam - no more than 10 minutes,

- accordingly, the length of the filled seam should be such that the master has time to apply and smooth the silicone before it sets. This parameter is determined individually.

- despite the fact that manufacturers indicate the time of complete cure 24 ... 48 hours, do not load the structure, in which the joints were filled, earlier than after 72 ... 240 hours. The duration of the "safety period" depends on the size of the seam, when filling large and deep cavities, you should multiply the base estimated time by 2 ... 3.

How much does silicone sealant dry for a bathroom

How long does the sealant dry in the bathroom? To answer this question, you need to understand that they are all divided into neutral and acidic. Each has its own characteristics and primary purpose. Neutral sealant is made on alcohol or its analogue (ketoxime). Some “models” contain antifungal supplements. The sour smell at work is from there. Heating pipes and radiators, drives, seams between the sink in the kitchen and bathroom, etc. - This is the entire field of application of neutral sealant.

Acidic ones are made on the basis of one or another acid. Its main purpose is gluing parts. Acid adversely affects metal (causes corrosion), natural stones (the natural color tarnishes), therefore, such sealants cannot be used on them.

Drying time

How long does a bath sealant dry? Drying time directly depends on the composition and the recommended area of application.

Acidic silicone sealant usually dries out after 4-6 hours from the moment of application, provided that the working surface has been prepared according to the rules (degreasing, cleaned of dirt and dust). Conventional neutral sealant dries within 24 hours. A prerequisite is the absence of negative temperatures! The room should be from 0 to 40 degrees (sweat at high temperatures there is a probability of violation of the structure of the sealant). In principle, each manufacturer gives their recommendations on the packaging. But still, certain technical points must be taken into account:

- no matter how thick the seam is, the material is applied in one pass. Multilayer application is unacceptable (in the end, seams will stratify),

By the way, you can order such a nozzle HERE. Many asked, accidentally stumbled 😉

- after the initial reaction, i.e. contact with air, the upper "crust" is formed after 15 minutes. At this time, if you inadvertently hook it, the entire seam may come off completely or the external texture of the seam (lumps, uneven relief) may break. In the inner layers, the reaction lasts accordingly longer. On average - 2mm layer (thickness) per day,

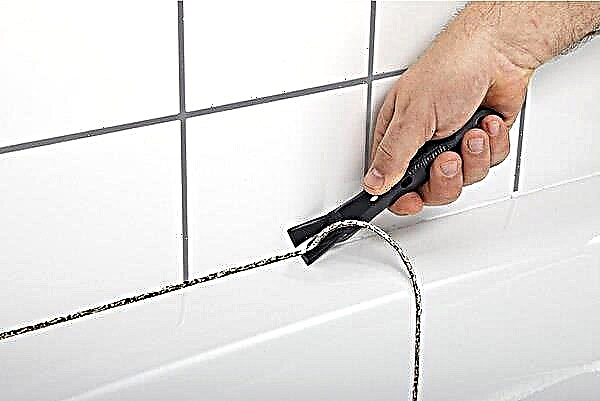

- joint between bathtub, sink, sink, stove, etc. may be wide. Consequently, the time for final hardening may need 1.5-3 times more than the manufacturer stated. Be patient, and if you need to check - check very carefully. External hardness can be very deceiving. Carelessly hooking or pulling the edge of the plank, you are in great risk of zeroing out all your work (you will have to remove and apply the sealant again).

How to speed up the drying time of a sealant

There are situations when repair work, for various reasons, needs to be accelerated, and as a result, accelerated drying time of silicone sealant. The following are basic ways to help the sealant dry faster.

- The higher the temperature, the faster the reaction. But do not go to extremes and do not try to help the material with a hairdryer or other “thermal” device of direct action. If the temperature point stated by the manufacturer is exceeded, your sealant will most likely completely collapse.

- The polymerization reaction is accelerated by two factors: air and moisture contained in it. Therefore, it is necessary to increase the flow of air, i.e. create a simple draft

- Sprinkle sealant with spray water or hold over steam. But in no case do not fill or lower the parts under water,

- Increase the room temperature. The boundary figure is +40. This is most conveniently done using a heat gun for stretch ceilings.

Sealant in the bathroom

How much does the sealant dry in conditions of high humidity in the bathroom? Again, this depends on the choice of the product itself:

- Silicone acid sealants dry the fastest - in 4-6 hours. But such a material cannot be used to work with metal structural elements so that corrosion of the metal does not occur.

- Neutral sealant is more versatile, but it costs more. Its 2 mm thick layer finally dries out per day, but at the same time there should only be a plus temperature. The most favorable range: from 5 to 40 degrees.

Applying sealant to joints in the bathroom

Applying sealant to joints in the bathroom

Important: Do not lay down several strips of sealant in one place, otherwise the whole point of this procedure will be lost and no sealing will occur, because the layers will peel off from each other. Apply immediately the strip of the desired thickness, just pressing harder on the trigger.

We accelerate the drying of the sealant

Now you already know how much the neutral and acid silicone silicone sealant dries.But in some cases I would like to speed up the process somewhat. It is possible to do so:

- By increasing the temperature in the room to 40 degrees.

- Opening all windows and doors to create maximum ventilation.

- By spraying already sealed seams with spray water. Moisture on the surface of the sealant will accelerate the process of polymerization.

Carefully inspect the sealant cartridge at the time of purchase. Make sure it is full, and also read the composition. The more different additives there, the less elastic the sealant will be. The price will tell a lot about the product. Quality sealant from a good manufacturer is more expensive.

How does the sealant polymerize?

Silicone sealant is a multi-component mixture. At the time of application, it is in a gel state. Further, upon contact with air, the solvent begins to evaporate, and the components of the composition undergo polymerization. The result is a mass that resembles rubber properties. This layer becomes a reliable barrier to moisture. It is simple and convenient to apply sealants, which is why they are used in many areas of construction and repair.

When installing plumbing equipment for the bathroom, toilet, kitchen, the deadlines are set tightly: the less time it takes to dry, the faster you can start using plumbing and sewage. At the same time, it is extremely undesirable to use plumbing until the sealing compound has completely dried: water under pressure will immediately wash the paste from the compounds, and all work will have to be started again. Therefore, it is very important to understand how the polymerization of the sealant occurs and how long these processes take.

Hardening takes place in two stages:

- In the first 25 minutes, a film forms on the surface of the composition. When this stage ends, the applied mass ceases to stick to the hands. However, under the solidified surface, the material is still in a gel state.

- Hardening the bulk of the applied composition takes a lot of time. Manufacturers indicate that the sealant on an acid solvent should dry for 5-7 hours, and on a neutral one - at least 24 hours.

The figures given are the average. For example, the Polish company Selena produces more than 30 varieties of sealants under the Titan brand. And different types of sealing compounds differ in polymerization rate. Therefore, before using the sealant, carefully read the instructions.

The final strength of the sealing mass acquires only after the second stage. In order not to wait for a whole day, it is necessary to understand what factors accelerate the polymerization.

Solvent type

According to the type of solvent, there are three main categories of sealants:

- Acetic acid based formulations. Their main advantage is quick hardening. However, acetic acid has a sharp characteristic odor, which will be felt not only during operation, but also for some time after application. In addition, this caustic substance can destroy concrete and provoke corrosion of metal products.

- Neutral compositions. Such mixtures do not destroy metals, are not afraid of contact with water. Colorless transparent sealant is almost invisible after drying. This variety is ideal for installing plastic windows, sealing joints on the floor, sealing the aquarium. A wide scope of application allows us to say that a sealant on a neutral basis is the most versatile of all varieties. But its drying time is 24 hours.

- In sanitary sealant bactericidal substances and components that prevent the appearance of mold are introduced. This composition is optimal for the kitchen, bathroom, living quarters. As a rule, mixtures of this group harden in 16-24 hours.

The choice of sealant by type of solvent is dictated by the scope.

When choosing a sealant, color plays a secondary role. Compositions based on acrylic or polyurethane are well stained with any paints. Only silicone sealants can not be painted, so they need to be selected by color.

Layer thickness

The thickness of the layer with which the sealant is applied is determined by the specifics of the work. For example, to seal the connection in plumbing, 1 mm of paste is enough, and to close the joint between the sink and the wall, it will be necessary to lay a much larger volume. Depending on the type of solvent, the polymerization rate is 2-3 mm per day.

No matter how much mass you need to lay to completely fill the seam, this is done at a time. If the sealant is applied in layers, one on top of the other, then after drying the mass will delaminate and the seam will become permeable to water. If you doubt that you can completely fill the space at a time, put more paste, and then remove the excess with a spatula.

Room temperature and humidity

Most manufacturers name two requirements for the microclimate in which the sealant will dry:

- The temperature should not fall below + 5 ° C and rise above + 40 ° C.

- The air in the room should be constantly updated.

In living rooms or on the street it is easy to achieve the necessary conditions - just open the windows (it would be a nice warm day) or turn on the fan. But when installing a bathtub or toilet bowl, it is much more difficult to ensure constant ventilation of a cramped room in which air is easily oversaturated with water vapor.

How to speed up the polymerization?

Professional installers know a few tricks to speed up the cure of the sealant. Here are some of the easiest ways to implement:

- Provide maximum ventilation. On fine days - open the windows wide, in cloudy and rainy weather - use fans. But it is important to ensure that dust does not land on the sealant.

- Heat the air in the room to a temperature close to maximum (+ 40 ° C). For this, an electric heater is suitable. But to warm the joint with a hairdryer is not worth it. Heating will be uneven, so different parts of the mass will harden at different speeds. This will adversely affect the reliability of the seam.

- Spray the joint from the spray gun from time to time. Humidification will speed up the hardening process.

- If it is necessary to seal the joints on the window frame with sealant, the composition will have to be dried with the windows closed. To prevent the frames from sticking tightly, after application, the composition is covered with foil. The paste will dry within 2–4 minutes, but to achieve the optimal result, you can only wait patiently.

These simple methods can help reduce sealant curing time by a few hours. Each hour won will allow you to complete the work faster and begin to enjoy the fruits of your labor.

Application area

There are several varieties of sealants, Each of them has its own scope and its own characteristics.

- For example, acrylic sealant is used for internal work. It can be used for wood, drywall, but it does not tolerate moisture and is not recommended for coatings exposed to high temperatures.

- Silicone sealant is used to grip any building surfaces, including metal or plastic. It steadily withstands various temperature conditions.

- The bitumen version is used to repair roofs, slate and tiles, it can be used in wet rooms. Suitable for sealing the drainage system. The vibration damping properties are lost at very low temperatures.

- Polyurethane is used for outdoor applications and does not depend on weather conditions.

Silicone

In 7-30 minutes after applying the silicone composition, initial polymerization will occur. The film that has appeared during this time is not recommended to be touched. Full solidification should be expected during the day. The average drying rate is 2 mm every day. At high temperatures, the average solidification time is multiplied by a factor of 1.5.

There are two options for silicone:

An acidic variety is the most common version of plumbing sealant. It is well suited to strengthen the joints between the bathroom and the wall, to seal the cracks around the toilet, but the sanitary type is undesirable on Teflon coatings and surfaces made of natural stone. Hardening time - 6-7 hours.

Quick-hardening varieties of acid silicone are on sale; the drying time when using them is 2 hours. There are other quick-drying options, for example, Moment sealant. The glue initially sets in 15 minutes, full hardening can be expected in a day.

The neutral version is suitable for working with almost any surface., This is a universal sealant that is suitable even for sealing a car engine and mirrors, but buying it can cost a pretty penny. It dries during the day, and the temperature conditions should be kept in the range from +5 to + 40 ° С.

Acrylic

Acrylic sealant can be waterproof and not waterproof, it is harmless and odorless. Hardening during its use can be expected after 12 hours, but, of course, it all depends on various factors. Sometimes complete drying can occur only after four weeks.

The cost of the acrylic option is about 1.5 times lower than other varieties, the lack of smell and harmful substances allows you to work indoors. Acrylic sealant is used for internal work, but there are products for external sealing - a frost-resistant option.

While the glue dries, it can be modified, rinse off excess tabs, the already hardened sealant can easily be cut with a sharp knife.

Bituminous

Bituminous sealant is also called roofing. It has strength, resistance to mechanical and chemical influences, tolerates various temperature conditions and is therefore used for outdoor work.

The following types of material are distinguished:

Bitumen-rubber sealant is widespread when working on a metal roof. It has elastic and plastic properties, is able to evenly spread over the metal, but does not drip. The material hardens after evaporation of the solvent, the drying time is 14-22 days.

The bitumen-polymer option is actively used for sheet and roll material, concrete, metal, plastic. Provides rapid elimination of leaks, seals joints and cavities, glues various roof fragments. When applying a layer of 3 mm, the formation of the primary film can be expected in an hour.

Polyurethane

The polyurethane version is similar in quality to polyurethane foam. It polymerizes under the influence of moisture formed in the air and dries quickly. Great for sealing interpanel seams, log joints, roofing, sealing windows and doors. Able to withstand severe climatic conditions.

These types of polyurethane are distinguished:

The one-component type dries due to contact with air or surface. Sometimes the coating can be slightly moistened. The strength of the sealant reaches one hour after application, and completely hardens after a day. At temperatures below 23 degrees, the drying period is extended.

The two-component view is mainly used on an industrial scale. Substances that are included in the composition are mixed immediately before work. The two-component solution can freeze in 30 minutes.

On sale there are individual silicone, acrylic, bitumen or polyurethane varieties of sealants designed for a narrow scope. For example, an aquarium or glass composition. From the name it is clear that this type is used for gluing mirrors or glass, but can also be used to work with ceramics, tiles, fiberglass and other materials.

Drying time depends on the thickness of the layer and the parameters of the glass, but usually the first film is formed after 15 minutes. Fully populate the glued aquarium is recommended only on the third day.

Separately, it is possible to distinguish red and black sealants, which are used both for construction purposes and in car repair. They can also include elements of both silicone and bitumen material - the drying time depends on these parameters.

They differ in pronounced color, and this is their advantage - classic sealants are colorless and poorly colorable.

What affects the cure rate?

All of the specified time frames for hardening the sealant are very arbitrary.

The actual term depends on the following factors:

- sealant specifications

- the presence of additives,

- features of the material of the work surface,

- temperature conditions

- applied layer thickness

- room humidity during operation,

- oxygen content in the air.

Recommendations

When working with sealant, use the following guidelines.

- If the sealant layer turned out to be voluminous, leave it without movement and loads for a period doubled from the average. Usually it is two days. Even if it seems that the material is dry, inside it can still be liquid.

- If you do not want to wait a long time until the silicone hardens, increase the air temperature to 40 ° C, create intensive ventilation, spray the joints with a spray of water. Moisture accelerates polymerization processes. All these actions will allow faster drying of the material.

- Refuse to buy acrylic when working in the bathroom. It is characterized by moisture intolerance.

- Use neutral sealant with fungicides for work in damp rooms. These substances inhibit the formation of fungi and mold.

- Do not purchase paper-based sealants. Check expiration date. Do not be tempted by too low a price.

Carefully study the composition on the packaging of the material. When wondering how long the sealant hardens, consider all of the above factors, as well as the information specified in the instructions.

- Time "to tack". This parameter indicates the time when the layer will no longer stick to the fingers.

- Final hardening. Includes the period from application to final strength.

- Application temperature. Determines the temperature regime at which operation is possible. When going beyond, the drying time changes.

- Permissible operating temperature. The specified interval allows you to keep the sealant strong, under other conditions, the characteristics may change.

- Shore hardness. The indicator of the strength of the material.

Thus, it is impossible to unequivocally answer the question of how much the sealant dries. It all depends on the type of material chosen, technical specifications, working and operating conditions.

See how to seal the joint between the bathroom and the wall with sealant in the next video.