It is impossible to distinguish the type of house whose sound insulation is better than others, everyone has a common problem - poor sound insulation of floors.

The peculiarity of prefabricated houses is that the massiveness of the floors and walls is the same, therefore the indirect sound transmission is very high. Sound in panel houses is transmitted from the upper floors down the walls, and soundproofing floor slabs is ineffective. In panel houses, it is recommended to perform full soundproofing of rooms, including the floor.

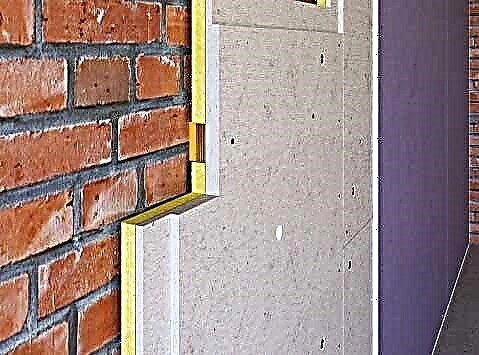

In brick houses, the walls are thicker than floor slabs, and the sound is damped in more massive structures. To reduce the noise level, it is often sufficient to modify only the ceiling.

In monolithic-frame houses, the overlap is more massive than room partitions, and the outer walls are often made of lightweight material. As a result, noise from floor slabs is transmitted to the apartment through partitions and load-bearing walls. In houses of this type, noise is being fought at the construction stage. Partitions are not built to the ceiling, but leave a gap of 10–20 mm; subsequently, it is filled with sound-absorbing material. From noisy neighbors on the side they are protected by partitions built according to the frame technology using soundproofing guide profiles. Noise from above is recommended to be reduced by means of a false soundproofing ceiling.

Noise protection materials are divided into two groups:

- Soundproofing - to protect noise penetrating from outside the house. The properties of the material increase with increasing thickness. Commonly used as part of special designs.

- Sound-absorbing - prevent the spread of noise outside the room. They have a fibrous or cellular structure that allows you to absorb sound. They are used to prevent the spread of sound (such as music) outside the room.

The noise level will drop sharply if you first attach a sound-absorbing material to the wall, and then soundproof.

To isolate apartments, most often they buy such insulators:

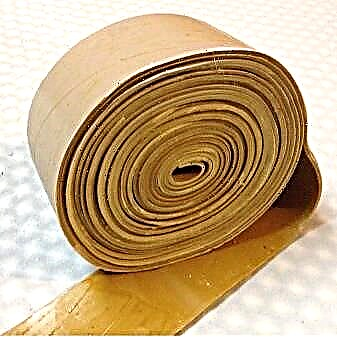

Mineral wool - retains more than 90 percent of all types of noise. Sold in rolls or slabs. The disadvantages include the loss of one’s ability after getting wet.

Cork is a natural soundproofing plate material. It delays shock noises well. The negative side is the high cost.

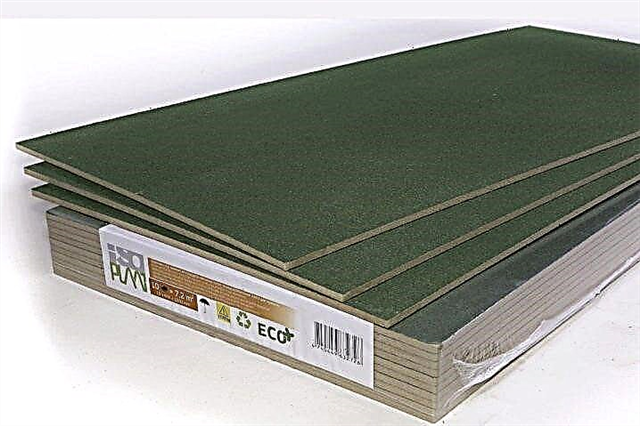

ISOPLAAT - soundproofing boards made of coniferous fiber to reduce all kinds of noise. Thickness - 10–25 mm, plate sizes 2700x1200 mm. One side is made smooth, under the finish.

ISOTEX - lightweight flexible coniferous fiber boards for protection against airborne and impact noise. Easy to mount, level walls.

ZIPS - panels of gypsum fiber and mineral wool with a thickness of 40 to 130 mm. Buy it and because of the ability to use instead of finishing walls.

Insulating material for use in apartments is chosen with a dense structure, about 60 kg / m3.

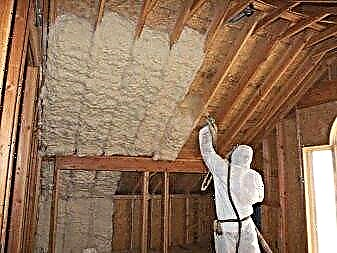

For noise insulation it is not recommended to use polystyrene foam, polyurethane foam, polyethylene foam. These materials protect the room well from impact noise, but they cannot lower the level of air noise.

Styrofoam

Polyfoam is called foam plastic, which consists of a large number of porous cells. It was this structure that allowed polystyrene foam and polyurethane foam to gain leadership among soundproof and heat-insulating materials.

Polyfoam is used for quite a long time for noise insulation of the ceiling. This material is characterized by low cost and ease of installation. Foam plates are attached to the surface with liquid nails, which a simple homemaker can do. However, despite its simplicity, the material perfectly isolates noises and extraneous sounds.

If we express sound absorption in numbers, then the foam absorbs up to 40% of sound at a frequency of up to 500 Hz. At higher frequencies, polyurethane foam is able to absorb noise almost completely.

Soundproofing walls: features

Installing soundproofing under the wallpaper will not be difficult if you delve into some of the subtleties. There is a difference in sound absorption from sound insulation. Absorption occurs if noise is heard from outside, and isolation is the sound of an apartment, the house does not go beyond the walls. Sound insulation features inherent:

- comfort - external sounds do not reach the residents of the apartment,

- there is sound insulation with a surface that does not require a finish coating,

- it’s possible to turn on loud music or talk until late at night,

- possess not only soundproofing properties, but also create thermal insulation.

Despite a number of features, there are drawbacks. Installation of some materials requires free space. The second drawback is a significant price, but it is justified by the above properties.

If the apartment or small house in the construction market has sound-absorbing wallpaper, as well as a lining for the coating.

There are completely turnkey solutions on the market - soundproofing systems ZIPS. They are panels that consist of several materials: dense and light. The hard layer is made of gypsum fiber, the light layer is made of mineral or glass wool. ZIPS has a number of important advantages:

- it does not have a metal frame,

- sandwich panels are easily mounted on walls,

- the material is fireproof,

- panels are equipped with special locking lamellas, providing high-quality docking.

Such products vary in thickness. The higher the noise level in the apartment, the thicker the material. They are mounted not only on monolithic walls, but also on drywall partitions. The thickness of the ZIPS-Vector panel is 40 mm, the ZIPS-Module is 70 mm, the ZIPS-Cinema is 120 mm.

This material has a drawback - it is heavy. One panel weighs about 20 kg.

How are such plates mounted:

- Before installing ZIPS products, preparatory work is carried out. The bases are completely cleaned and leveled.

- At the joints of surfaces intersecting with the insulated wall (ceiling, floor, other walls), anti-vibration tape (Vibrostek-M) is used.

- Through special vibration nodes, the panels are mounted with dowels.

- For sealing joints, silicone sealant is used.

- The wall component is completed by the last component of the system - drywall, which is fastened with self-tapping screws 3.9 x 41 mm. Manufacturers recommend using GKLA (acoustic drywall), for example Gyproc AKU-line.

How to choose a material for sound insulation

It is necessary to start thinking about this at the design stage. Since you have already decided to carry out such an operation as the soundproofing of the ceiling, materials play, perhaps, a paramount role

It is important to know which ones do best with the sounds in your apartment.

There are several types of sounds depending on the type of distribution:

Airborne noise. This type of sound appears during the operation of the radio, television, conversations of people and communication of animals. You can get rid of it with the help of fibrous or porous materials.

Shock noise. Very often we feel it during repair

And it doesn’t matter whether it passes by the neighbors or we decided to equip our house. Alternatively, a child or girl stomping upstairs can bother a lot, running down the stairs in high heels every five minutes

Salvation from these terrible sounds will provide material with a closed cellular structure.

Structural noise. It includes all of the above sources of irritation, but is transmitted not through the air, but through structures, especially metal ones.

Sound insulation under a stretch ceiling

Sound insulation under a suspended ceiling on the frame. Minimum construction thickness 110 mm. Index of additional insulation of airborne noise: ΔRw = 14 - 16 dB.

The most effective noise isolation under a stretch ceiling is a device on the ceiling of a noise-proof suspended ceiling. The design of the suspended ceiling contains all the elements (layers) necessary for reflection, dispersion and absorption of sound energy in a wide frequency range.

Noise protection for floors under a stretch ceiling does not impose special requirements for leveling and surface finishing. For this reason, some changes can be made to the design of the suspended ceiling.

For example, for covering the ceiling, both for the outer and inner layers, gypsum fiber sheets are used. This material is more dense than GCR, which improves sound insulation.

If it is not planned to lay a viscoelastic membrane between the sheathing sheets, then sheathing is performed in one layer with sheets of increased thickness. True, such a decision will worsen sound insulation.

For paneling on the frame, you can also use acoustic panels from the Fonstar corrugated cardboard (PhoneStar) in one layer.

Noise-reducing suspended ceiling of the minimum height

In order not to greatly reduce the height of the room, the thickness of noise insulation under a stretch ceiling in an apartment is often tried to be made smaller.

As noise insulation under a stretch ceiling, it is advantageous to arrange a suspended ceiling of a minimum thickness of 55 mm.

An elastic substrate, for example, an acoustic sheet or soundproof mats with a thickness of 10-20 mm, is laid on the ceiling over the entire area. The substrate is fixed to the ceiling on dowel mushrooms 70 mm long (2-3 fungi per 1 m2). The sheets are overlapped by 4-5 cm. The joints of the panels are sealed with mounting tape with reinforcement.

Profiles of metal frame PP 60/27 mm. fixed without vibration suspensions, directly to the overlap through the substrate. For fastening profiles, special acoustic dowels are used - nails. The absence of vibration suspensions of course reduces the noise-proofing properties of the coating.

At the points of attachment of the frame to the overlap, the substrate is compressed and acts as a damper, which reduces vibration transmission. Over the remaining area of the ceiling, the material works to absorb sound waves due to its fibrous structure.

The gaps between the profiles can be additionally filled with sound-absorbing material - thin acoustic slabs of mineral wool or mats.

The ceiling system must be vibration-proofed from the walls. Under the guide profiles, it is necessary to lay the damping tape in two layers.

Cork Wallpaper

You can get such wallpapers in any hardware store. Presented in several solutions for every taste. Allow to solve such problems:

- Create an unusual room design,

- Get rid of most of the outside noise.

Allows you to get rid of most of the outside noise.

Possible other options

One of the possible alternative options for noise absorption is the use of a plastic film for wallpaper. Such material is inexpensive, but has excellent noise protection properties. It does not require special training.

Such material is inexpensive, but has excellent noise protection properties.

Why is it necessary

- counteraction to all 4 types of noise waves: air (conversations, music), acoustic (echo), shock (repair work), structural (staircase elevator noise),

- restriction of noise flow coming from your apartment,

- additional insulation

- comfort and harmony at any time of the day.

Pay attention to the second point - thanks to the soundproofing of wall surfaces, you not only limit the sound stream entering your apartment, but also stop the propagation of noise waves that come from you. Of course, it's hard to believe (sarcasm!), But sometimes we ourselves become involuntary sources of annoying noise

Therefore, to ensure that this is not the case is a direct sequence on your part that perfectly illustrates integrity and honesty.

The types of noise that may occur in the apartment

All noise vibrations arising in the apartment are divided into three types:

- Airborne noise. In this case, we are talking about air vibrations that are created during a conversation, from a working TV or a closing door.

- Shock noises are created as a result of mechanical impact on the ceiling. It can be a stomp or a driven nail.

- Structural noise is created by the elevator, ventilation, plumbing system and other communications in the house.

Now we should deal with the question of how noises of different nature get into the apartment. This occurs for the following reasons:

- During the construction of the house, the soundproofing of the floors was not performed or the technology of this process was violated.

- In the ceilings there are cracks and cracks that conduct noise.

In addition, noise can pass through joints in the heating and water supply systems.

Soundproofing in the apartment: tips and tricks

- Only a competent combination of sound-absorbing and sound-reflecting materials provides high noise insulation of the room.

- You can’t just stick foam sheets on walls or ceilings, then cover them with plaster. Such a “soundproof cake” does not increase, but reduces sound insulation.

Soundproofing the floor in the apartment

Any soundproofing material is best installed as part of soundproofing structures. Even gluing surfaces with superthin soundproof membranes does not increase the acoustic characteristics of the room.

Do not install soundproof structures if their total thickness does not exceed 10–20 millimeters.

Mineral wool mats

Do not forget about the aesthetic characteristics of soundproof materials. The design of the apartment should not spoil the massive construction of the ceiling or walls.

Stay tuned for innovative developments in the field of sound insulation - new materials often have higher quality at a relatively low cost.

Soundproofing the walls and ceiling with your own hands is a perfectly feasible task. If you seriously and thoroughly approach the process, then the result of such sound insulation will far exceed your expectations.

Acoustic plates and mineral wool

Very often, the soundproofing of the ceiling is performed using mineral wool, which is also considered one of the most common soundproofing materials. Mineral wool is a fibrous substance consisting of the finest strands of molten rock or glass. The material is delivered to commercial enterprises in roll form or in plates. At medium sound frequencies, sound insulation with mineral wool 5 cm thick absorbs up to 76% of noise and sounds.

Unlike polystyrene foam, mineral wool does not burn, but smolders, while the temperature should be quite high. Fungi and bacteria do not multiply in mineral wool, therefore, the process of decay in such sound insulation does not proceed. Among the disadvantages of the material, high hygroscopicity can be distinguished, which becomes the reason for the decrease in heat-insulating and sound-insulating characteristics. To solve this problem, additional waterproofing is performed.

One of the derivatives of mineral wool are acoustic plates, which are characterized by increased sound absorption. The outer layer of such a material simultaneously acts as a waterproofing, sealing and soundproofing surface. The inside of the plate is impregnated with a hydrophobic composition, due to which it does not absorb moisture.

In the production of Schumannet acoustic slabs for the ceiling, all criteria that increase the soundproofing properties are taken into account. In particular, we are talking about the following:

- The location of the fibers.

- The length and thickness of the fiber.

- The elasticity and density of the fibers.

- Characteristics of the binder.

- Blown material.

Thanks to this technology, the output produces products that absorb noise as much as possible. Therefore, acoustic plates are used in the arrangement of soundproofing systems in cinemas, theaters and recording studios.

Features of monolithic frame houses

Monolithic frame construction is characterized by the presence of heavy interfloor ceilings and light internal partitions, which easily pass sound waves. In addition, the use of modern lightweight materials (hollow brick, foam concrete) for the construction of external walls contributes to increased thermal insulation and noise transmission.

Regardless of the variety, soundproofing for the ceiling in the apartment is an important stage of decoration, since its quality and literacy determines the level of comfortable and relaxing stay of all residents. Today, with the help of modern materials and construction technologies, this problem is easily solved, despite the complexity and time of detection.

The most common methods of ceiling sound insulation include the installation of an acoustic suspended ceiling, as well as the installation of drywall sheets with embedded soundproof plates of any of the following materials:

- foam glass

- basalt wool

- reed plate,

- fireclay

- peat insulation boards,

- polyurethane foam blocks,

- staple fiberglass

- linen tow in mats,

- cork coating

- coconut fiber.

Reliable ceiling sound insulation is performed from an additional ceiling system in the form of:

- suspended ceiling - to a metal frame equipped on top of the old ceiling, plates of the selected material are attached,

- false ceiling - gypsum cardboard is screwed on top of the metal frame.

- stretch ceiling with sound insulation - to the installed special brackets, a textile cover made of film is attached.

Soundproofing Work Plan

Noise isolation of the apartment consists in the integrated implementation of special materials that absorb sound waves into the supporting structures of the room. Such materials are used for floors, walls or ceilings, significantly limiting the distribution of sounds.

Before proceeding to the actual sound insulation, you need to decide on the following questions:

- The nature of the noise:

- Airy - constant household noises created by objects or sounds,

- Percussion - created by striking objects or objects. The culprits of such noise are often children or prolonged repairs.

Sound wave propagation directions

In which room is insulation required:

- In the bedroom - if you cannot fall asleep from the noise of your neighbors,

- In the living room - if you yourself like to take noisy companies until the morning,

- In the nursery - if your children love outdoor and noisy games.

What surfaces will be involved:

- If annoying noise comes from below - do noise insulation on the floor,

- Unless you live on the top floor, you have to hear the steps of the neighbors living upstairs all the time. In this case, noise insulation of the ceiling is necessary,

- If you like complete silence, you will need complete insulation of the apartment,

- In most cases, it is enough to isolate only walls from noise.

Drywall reflects sound, and soundproofing material absorbs it

What sound insulation materials do you plan to use:

- When decorating walls, plasterboard is considered the most common material today. But this material has a strong reflection coefficient of sound, so it is good for a bedroom, but not too suitable for a living room with a home theater. But gypsum panels, also used in wall decoration, almost do not reduce the sound quality in the room.

- Modern soundproofing of the ceiling significantly reduces the noise level in the apartment, and improves its sound-absorbing characteristics. In rooms where absorption, rather than reflection of sound, is required, stretch ceilings have proven themselves well.

Soundproofing floor scheme

Soundproofing can be carried out in two directions:

- Elimination of defects of builders made during the construction or operation of the house. Such simple measures can dramatically improve sound comfort in any apartment.

Constructive measures to improve sound insulation. There are many modern designs, materials and technologies to increase the noise insulation characteristics of an apartment:

- installation of the "floating floor" design,

- installation of a noise-insulating false ceiling,

- installation of noise insulation screens for walls, partitions,

- soundproofing of air conditioners, ventilation systems, etc.

Soundproofing walls and ceilings should always begin with a careful search for cracks and holes. All cracks and holes found must be puttied. Complete this simple task and your walls will begin to absorb more noise.

DIY sound insulation installation

How to mount sound insulation is a topical issue for those who understand which insulator to use. As an example, consider the installation instructions for "Shumanet BM" on the surface of the walls.

The work proceeds as follows:

- First, the wall is cleaned of dirt and primed,

- Further, marking is applied to the surface - so that the crate can be fixed. The dimensions of the plates are used to determine the pitch of the frame. The standard size is 500 mm, that is, the pitch will be 450-485 mm,

- Now the details of the crate are fixed (best on a wooden frame). Between the frame elements and the wall is a soundproof layer of any thin material,

- Soundproofing

- A vapor-permeable membrane is placed on the sound insulation,

- The installation of the cladding is being carried out - plasterboard sheets are ideal for this.

We also offer to watch a video on the topic - it will help to understand all the nuances when installing sound insulation (beginners usually have a lot of questions).

Everyone understands - comfort is very important, especially at home. Silence is achievable in any room, the main thing is to properly soundproof the ceiling and walls. Success is also largely determined by the materials chosen to solve this problem.

What you need to know about soundproofing apartments

The market offers a lot of offers with different prices, but how to choose the right sound-absorbing material? It is important that such products have two main properties: soundproof and sound absorbing. For example, the following Ruspenel Comfort product relates specifically to soundproofing materials.

It consists of extruded polystyrene and fiberboard, on one side the Comfort panel is covered with a polymer-cement composition, which allows it to be applied with any final finish

For example, the next Ruspenel Comfort product relates specifically to soundproof materials. It consists of extruded polystyrene and fiberboard, on the one hand the Comfort panel is covered with a polymer-cement composition, which allows it to be applied with any final finish.

To indicate the degree of product performance, a special RW coefficient is used, which is measured in decibels. It shows what noise level reflects the selected material. The table below shows this coefficient for special soundproofing panels of various types.

However, recently the production of building materials has taken a big step forward, so now you can safely arrange soundproofing of the walls without losing the space of the living space. Modern technologies make it possible to create thinner panels that are not inferior in properties to frame multilayer structures. Before, the process of installing sound insulation was really complicated. After such processing of the walls, the room was significantly reduced in size.

Models

The Russian market has many attractive solutions for protection against extraneous noise. The sound attenuation level of these products is as follows:

ZIPS 4 cm - 10 dB,

ZIPS 13 cm - 20 dB,

Isotex 12 cm - 23 dB

Isoplaat 10 cm - 23 dB.

These figures relate to airborne noise. Choosing soundproofing means, it is necessary to take into account the size of the room where they will be mounted, the level of humidity and temperature difference. Since thick and multilayer systems are quite heavy, even when using relatively light substances, floors and walls must withstand a certain load.

Hard soundproofing materials cannot have an absorption coefficient greater than 0.5. This group includes:

granular mineral wool

For semi-rigid materials, the sound insulation level rises to 0.75. Typical options are polyurethane foam, pressed mineral wool and styrofoam. But maximum protection is provided only by soft coatings (such as glass wool, foam rubber and stone wool).

Features of the installation of soundproofing

The choice of soundproofing material and the installation method depend on the noise level and structural features of the room. With low acoustic permeability or low ceiling level, frameless or glued insulation can be used. If the room has high ceilings and significant acoustic permeability, installation of a frame system is required.

Sealing between joints

Okay way

Okayechnaya sound insulation of the ceiling in the apartment is the easiest way to install a protective layer that reduces the sound permeability of ceiling structures. Most often, it is used as a base on which decorative decoration is applied. Rolled acoustic membranes are glued directly to the surface of the ceiling using glue or vibration sealant. Some manufacturers produce coatings with a self-adhesive layer, which greatly simplifies installation.

Features

All sounds that can be heard in an apartment or house are divided into two groups: air and percussion. The first includes sound waves propagating through the air:

- the sound of traveling vehicles

- conversations

- music and soundtrack of films (videos),

- phone calls, doorbells and knocking.

Impact noise occurs when something acts on walls, floors and floors in an apartment or private house. It is shock noises that cause the most problems during repair, they arise when something falls to the floor, when furniture is moved, dance, when children or animals are running fast. Sound-absorbing materials and structures should ideally cope with both varieties of harmful sounds.

Advantages and disadvantages

ZIPS type panels are structurally made as a sandwich based on fiberglass or mineral wool. The solid part of the structure is gypsum fiber sheet. It should be noted that fiberglass is not suitable for home use, it poses a great threat to health. ZIPS panels make it possible to provide quick and relatively light sound insulation, and the noise-absorbing properties are quite large with respect to both air and impact noise. In addition, they do not need to create a frame.

But keep in mind that such a solution is quite expensive, and the total thickness of the structure sometimes reaches 130 mm.

Noise-isolating membranes "Texound" appeared relatively recently and have a number of positive aspects:

- flexibility and simplicity of laying,

- excellent airborne noise reduction and long life,

- resistance to moisture and the minimum occupied space.

The only disadvantage of membranes is the significant price.

Classical insulation with mineral wool (it is also basaltic) is very popular due to the effective fight against impact noise, long-term operation, and resistance to cold. But it is necessary to supplement such a material with a moisture-proof coating, otherwise it will quickly fail.

Cork noise protection is available in the form of rolls or plates (the latter may have a thickness of up to 30 mm), the coating is held on the wall surface with a layer of glue. The cork looks attractive, it is environmentally friendly material, but judging by the reviews, while it mainly inhibits shock noises, the sound propagating through the air is suppressed worse.

You can find out how to make a ceiling sound insulation with your own hands in the next video.

Material selection

Currently, the market has a wide range of building materials that can protect against noise. High-quality noise insulation materials effectively cope with their task. In order not to make a mistake in the choice, it is worth paying attention to the following characteristics of the material: thickness, soundproof coefficient, combustibility, as well as the absence of substances harmful to the body.

ZIPS panels

ZIPS panel is a sandwich panel, consists of two layers: fiberglass (mineral wool) and gypsum fiber sheet. It is attached to the surface with special nodes, and between them - with the help of a tongue-and-groove connection. Such a system is good for soundproofing the ceiling.

Its advantages include: quick and easy installation of soundproofing (you can handle it yourself), good soundproofing of air and shock noises, lack of a metal frame, fire safety, high-quality docking of panels.

The downside is the price: you will have to fork out for such panels. Other disadvantages include excessive thickness (up to 13 cm) and material weight (one panel can weigh 20 kg).

Tecsound

New to the market of soundproof panels. It consists of thin aragonite membranes. Aragonite is a natural mineral that has unique properties that give the material elasticity and good sound absorption.

It has a lot of positive reviews, among which are especially noted: flexibility and ease of installation, good protection against airborne noise, durability, moisture resistance, resistance to decay, the ability to install in small rooms, due to its small thickness.

Only one minus, but significant - high cost. It is most effective to use this sound insulation together with mineral wool sound insulators providing sound absorption.

Mineral wool and slabs

Mineral (basalt) wool and slabs are made from non-combustible raw materials that do not shrink. The use of cotton wool with plates gives a good effect, however, this can significantly reduce the height of the ceiling. In low rooms, this option should be discarded.

The advantages of this material are: a significant reduction in impact noise, durability, frost resistance, fire safety, environmental friendliness, heat preservation in the room, simplified preparation for installation.

Cons: it easily absorbs water, so you need to provide protection from moisture, a danger to human health - you need high-quality insulation to neutralize the harmful effects.

Isoplaat

This sound insulation is a material in the form of boards made of coniferous wood. Thickness is from 10 to 25 mm. This sound insulation can cope with the absorption of external noise. Apartment owners often give her their preference.

Among the main advantages can be noted: affordable price, good sound insulation, environmental friendliness, providing noise protection and good thermal insulation, small thickness.

The only serious drawback is the high cost.

Acoustic panels

Modern models are made from innovative materials (for example, foam granulate with a bunch of inorganic substances), which have high sound-absorbing characteristics. A feature of such panels is the creation of high-quality acoustics. This helps to significantly increase the acoustic comfort of the room.

The advantages of this material include: environmental friendliness, excellent sound insulation of rooms, ease of installation, creation of acoustic comfort, unlimited term of use.

It is often used to decorate the premises of rehearsal points or recording studios.

Polyurethane foam

This material has a wide scope. More often it is found in small noise insulation works, in everyday life it is applicable in the form of polyurethane foam (voids are filled with it).

The advantages of such sound insulation are: durability, ease of installation, biological inertness, the ability to completely seal the room, lightness, significant insulation of the room, protection from shock and airborne noise due to tight adhesion, absorption of internal and external noise.

Minus: fire toxicity. Because of this, it is considered dangerous.

Sound absorbing materials must be chosen wisely. Depending on the purpose and place of use, the material itself may change. A competent approach to solving this problem will provide long peace and quiet in the house.

In the next video you will see the testing of noise insulation materials.

Advantages and disadvantages of soundproof panels

It is important to understand some points about sound insulation. There are two principles to combat noise:

- Sound absorbing panels. The material is porous, so that the sound coming from the outside is absorbed by the panel.

- Soundproof. Such panels are made of hard fibers. They are able to reflect almost all the sounds that enter the room from the outside.

It is about the second type of products that we will talk about. A panel is a product of a certain size with a certain soundproofing material. It can be used for decoration material or have decorative properties in which additional decoration is not required.

Advantages of soundproofing panels:

- Small thickness. In small apartments, every centimeter is very expensive. If you use plates for soundproofing the walls, the area of the room is practically unchanged.

- Light weight. Transporting and transporting slabs is easy. In addition, they do not load the wall structure. If you cover a section of the wall with an area of 1.5 m2, then the used boards will have a mass of not more than 4 kg.

- Multifunctionality. Soundproofing panels for walls, which consist of more than two layers, can absorb sound, retain heat inside and perform a decorative function.

- Simplicity and ease of installation. The whole process does not require dirty and wet work, construction debris, dust and dirt are absent. To perform the work, high-tech tools are not needed. The walls do not need to be additionally prepared: drill, putty, thoroughly clean from the previous layer. If necessary, the dismantling of products is even easier.

- Decorative soundproofing panels have various decorative coatings. The front layer can be made of vinyl, textile, wood, in the form of paper wallpaper. Thanks to this assortment, you can choose the option that is ideal for the created interior.

- Universality of use. The material is acceptable for soundproofing walls in an apartment, in a private house, in industrial, commercial and office buildings. In this case, you can fix the panel to any surface. For example, to a concrete wall, foam block, wooden wall, or to a frame structure. Most importantly, the old finishing material (paint, wallpaper, plaster) will not affect the strength and reliability of the connection.

However, decorative noise insulation panels have some disadvantages:

- To get a good result and improve sound insulation, you need to finish the entire room, not just one surface,

- High price. Modern multi-layer panels, which have a small thickness and maximum performance, will cost more than traditional materials.

Nevertheless, the high price is due to the excellent quality, moreover, the panels serve both for sound insulation and as a decorative finishing layer. And since the entire installation process is not difficult, you can save on hiring workers by doing all the work yourself. And now we will consider what types of products can be used for rooms.

Abbreviation ZIPS - Soundproofing panel systems. This is a complete solution. The product combines several materials, light and dense. The dense hard layer is gypsum fiber, and the light one is mineral or glass wool.

ZIPS has several positive aspects:

- The system does not have a metal frame, which affects the weight.

- The sandwich panels are simply fixed to the wall.

- RW for products is 10 dB.

- Products are fireproof.

- The panels have special locking lamellas, thanks to which they perfectly fit together.

ZIPS products differ in thickness. At the same time, the principle works: the more noise indoors, the thicker the panel is required. Installation can be carried out both on monolithic walls and on partitions made of drywall sheets.

The thickness of the ZIPS-Vector is 4 cm, the ZIPS-Module is 7 cm, and the ZIPS-Cinema is 12 cm thick.

The disadvantage of the soundproof panel is that it is heavy. One such plate can weigh about 20 kg.

- Before installation, banal cleaning of the base is performed. It needs to be cleaned and leveled.

- At the joints of surfaces with each other (places of the floor and walls, ceiling and walls, etc.), you must additionally use anti-vibration tape, for example, Vibrostek-M.

- Through vibrating nodes ZIPS are fixed in place by means of dowels.

- The remaining joints must be sealed with silicone sealant.

- You can finish the cladding work with the last component of the system - drywall. It is fixed by means of self-tapping screws (3.9x41 mm).

Mineral wool panels

Similar acoustic panels for walls are made of mineral wool, which is well pressed. The product fully performs two types of functions: it protects the room from sound penetration, and also retains heat indoors. In winter, the rooms will be warm, and in summer it will be cool.

Convenience and the main difference between the mineral wool panel and ZIPS is that for its installation it is not necessary to prepare the base: to clean the wall and level it. It is enough to install a metal or wood frame on the walls, and then lay the mineral wool slabs in the created cells. Accordingly, the cell sizes are selected based on the width of the plate itself.

Advice! To improve sound and heat insulation properties, the material is laid in two layers.

After all the walls are covered with slabs, it is enough to sheathe them with plasterboard sheets. You need to understand that when installing the frame under any soundproofing material, it is important to use special suspensions with anti-vibration inserts. They serve to reduce the transmission of vibrations from overlapping. A soundproofing tape or soundproofing material must be placed under the frame guides.

EcoZvukoIzol panels

Under this name, the products of the national SoundGuard campaign are produced. The material is made from several types of cardboard. Two layers are made from ordinary flat cardboard, the rest from profiled. In total, the soundproofing board has 7 layers.

The resulting voids inside are filled with quartz sand. And although this is not the most economical option, the soundproofing properties of the panels are excellent. Ecological purity of products is also pleasing. But, due to the addition of sand to the composition, the weight increases and can reach 10 kg per element.

The thickness of EcoZvukoIzola varies depending on the model:

- slim - 1.1 cm

- standart - 1.2 cm

- EcoZvukoIzol - 1.3 cm,

- Premium - 1.8 cm.

There are several options for fixing panels to the wall:

- Mounting adhesive for drywall sheets.

- Plastic dowels.

- Dowel nails.

- On a metal or wood frame.

Before installation, wall preparation, cleaning and alignment are required. After installing the sound-absorbing layer, the frame is sheathed with gypsum plasterboard or gypsum plasterboard. They are fixed on glue or screws.

Isotex

Separately, I want to highlight Isotex. This is a multilayer soundproofing board manufactured by a Finnish company. The sound and heat-insulating material Isoplast is the basis, the thickness of which is 1.2 cm. These are decorative panels for soundproofing the walls in the apartment, since the front part is always decorated with wallpaper, paper or vinyl with plain linen. The peculiarity of the panels with wallpaper is that, if necessary, they can be repainted, as well as washed regularly.

The material is environmentally friendly and made from natural wood. There are no chemical components in it, so the stoves are used even in children's rooms. The structure of the coating is porous, it is not afraid of temperature extremes and high humidity. This is not a flammable material.

If the exterior finish is made of textiles in 4 colors, then care is carried out exclusively by dry cleaning.

Soundproof Membranes

This is a roll type of material that can be called the simplest and most affordable. Often, these options are sold with a self-adhesive layer. A distinctive feature of soundproof membranes is their thickness. Although the products are thin, they are durable. In addition, the material copes well with noise protection. According to experts, when using products, the noise level drops to 28 dB.

A thin layer of 5 cm will cope with sound absorption like a concrete wall 30 cm thick.

This soundproofing is universal and suitable for any room. It is elastic and not afraid of temperature changes. Ecological cleanliness and fire safety of products are also pleasing.

As you can see, soundproofing with panels or roll material is a great option to provide peace and comfort in the house. In addition, most types of products also have a thermal insulation and decorative function. It remains only to compare the types of materials, evaluate the pros and cons, and then do the installation of the plates with your own hands. At the same time, soundproof panels for the ceiling and walls are available on the market.

Frameless system

This is the installation of drywall, cork or chipboard, sandwich panels, which are made directly to the ceiling. In order for this method to lead to the desired result, the following rules must be observed:

- a layer of thin roll insulation is glued to the ceiling,

- a rigid plate or panel is screwed to the ceiling, without using a profile system,

- joints are treated with vibration sealant,

- a finishing coat is applied corresponding to the type of material used.

Such a soundproofing layer slightly lowers the ceiling, but also has a drawback. The design works with airborne noise, but protects against shock not efficiently.

Wireframe system

The installation of the frame system is the most reliable sound insulation of the ceiling in the apartment. The only drawback of such a system is the lowering of the ceiling level, to 10-15 cm. The frame is mounted on the ceiling, filled with acoustic material, and then closed with a soundproof plate or panel.

Ceiling Sound Frame System

In order for the system to match the functional purpose, it is necessary to install it correctly. Mount frame insulation as follows:

- joints of plates and all openings in the ceiling are treated with acoustic sealant that dampens vibrations,

- a profile frame is mounted on the walls around the perimeter, under which a vibrational sealing tape is necessarily laid,

- the profile is fixed with special vibration suspensions equipped with anti-vibration tabs,

- mineral mats, polystyrene foam or liquid polyurethane foam are sprayed into the finished frame,

- mounted on the profile ZIPS, acoustic drywall or other type of solid panels, plates,

- the finish layer of drywall is fixed to the coating, overlapping the internal joints,

- seams are treated with vibro-sealant and applied finish.

As an additional soundproofing layer, before installing the profile on the ceiling, you can stick an acoustic membrane. The frame system is also suitable for suspended ceilings, enhancing both air and shock absorption.

When installing the ceiling sound insulation in an apartment, you must correctly select the material and the way in which the installation of the acoustic barrier will be performed. The degree of protection of acoustic materials depends on their individual characteristics. When choosing a coating, be guided by information on the degree of sound absorption and soundproofing properties indicated on the package or in accompanying documents. Remember that gluing and frameless methods will not protect the room from shock and structural noise. Also, the frame system may turn out to be ineffective if it is made with violations of installation technology.

Soundproofing the ceiling in a private house - will be discussed in the next article.

In what cases do soundproof panels help?

In modern apartment buildings, the wall thickness is small, therefore, the soundproofing qualities of the building are low. With the use of soundproofing materials, it is possible to provide comfortable living conditions. In apartments, there are two types of noise that are inconvenient and can even cause a nervous system disease.

@PaneliZvukoizolyatsii

Airborne noise is transmitted by air from which such a name. As a rule, such sounds get into the apartment when people talk loudly, listen to music or watch TV. In addition to the air, there is still vibration, which can be transmitted on solid surfaces. Vibrating noises include a working power tool, hammer blows, or a working washing machine. The only escape from noise is the soundproofing of the walls.

It's important to know!To effectively protect the house, it is better to use integrated sound insulation, which is installed not only on the surface of the walls, but also the floor and ceiling.

Today, with the advent of new technology for the manufacture of decorative noise insulation panels, it is possible not only to protect housing from various noises, but also to create a unique interior design. Modern decorative plates in their properties are superior to materials such as: drywall, particleboard and fiberboard.

Advantages of decorative soundproofing panels

Decorative soundproofing boards have a lot of advantages, thanks to which the material, despite its recent appearance, quickly gained popularity among buyers.

- Panel thickness. When decorative noise insulation is mounted in an apartment, the usable area is reduced due to the installation of the frame and the protection of panel sheets. Such a noise insulation design takes at least ten centimeters from each wall. If we summarize all the values, then there would be enough space to install a refrigerator or a washing machine. Decorative panels provide a high degree of sound protection without compromising the available space.

- Mass of material. The weight of the product is relatively small, which makes it possible to independently carry out installation work even without the involvement of specialists and assistants. The mass of one plate is 4 kilograms, while it covers one and a half squares.

- Functionality. Soundproof decorative panel consists of different materials. The composition of the panel includes: a noise insulation layer, a heat insulation layer and a decorative finish. One panel performs three functions simultaneously.

- Features of installation.It is worth noting that with the use of decorative insulating panels it is not necessary to take out a lot of construction debris, use many different tools, and also prepare the machined wall surfaces. Thanks to these characteristics, you can significantly save on noise insulation and repair in general.

- A variety of design options. Everyone during the repair wants his room not to be like any other. An abundance of options for texture and materials used in the decoration allow you to recreate your fantasies in real form. Among all the abundance, everyone will be able to find what he needs.

- Universal material. Unlike different soundproof materials, which vary in structure and characteristics, decorative panels are suitable for any room. From the kitchen to the public dining rooms. The panels can be installed on any surface, including for the ceiling, while the performance characteristics of the structure do not change.

Interesting! The scope of decorative soundproofing panels is very extensive, so the material is in demand not only in residential buildings, but also in general use.

Disadvantages

No matter how magnificent the material is, it still has some drawbacks. One and perhaps the most important disadvantage of decorative soundproofing panels is the high cost. If you compare the installation of the simplest soundproofing frame type, then it will cost the owner several times cheaper than acquiring sound-absorbing panels, decorative plates.

@PaneliZvukoizolyatsii

Although if you consider everything in more detail, it turns out that for standard sound insulation it is necessary to additionally finish the walls, ceilings and floors. In the case of the use of decorative plates, you do not need to do anything, since the products are already distinguished by their attractiveness.

Advice!They install decorative panels for sound insulation according to different technologies. If the surface of the walls is perfectly flat, then you can use ordinary liquid nails, which reliably and firmly fix the decorative element.

Overview of soundproofed wall panels

Today, Russian manufacturers supply the market with two types of panels: isotex and haltex. Each of the options has its own qualities and features. Selecting the material, it is necessary to take into account all its structural features and characteristics. Modern technologies are improving every day, which contributes to the development of building and finishing materials. Today, many people make design changes using innovative materials, because such products have much more advantages than other finishes.

@PaneliZvukoizolyatsii

Halltex

The Finnish manufacturer, who offered his products recently, but she was able to gain popularity among consumers. High-quality noise-insulating material with a decorative coating becomes an alternative solution for apartments, offices and public premises. The material has a number of advantages due to which it can compete with similar types of materials.

@PaneliZvukoizolyatsii

As part of decorative panels, only natural components are used: wood chips and adhesive mortar, used in the food industry. Due to the environmental friendliness of the product, it can be used for residential premises and children's rooms.

Exterior Coating Design

Using decorative soundproof plates, the acoustic performance of the room can be significantly improved. There are four main types of textile coating. Depending on preferences, you can choose exactly what is needed. Fabric-based panels must be looked after in accordance with the manufacturer's requirements. Fabric panels require dry cleaning, so this feature must be considered. The decorative panel is much more durable than the best wallpapers. If the design of the apartment is changing, then the panels can be repainted, thereby creating a new look for the existing room.

@PaneliZvukoizolyatsii

Production and composition

The production technology includes the manufacture of wood chip boards. The raw material is crushed to a fine fraction, after which the composition is filled with water and formed on the mold into a product. The adhesive of the boards is natural resin. Due to the environmental cleanliness of the material, the scope of decorative plates is very extensive, and the variety of textures allows you to choose a product for any interior design.

Panel Installation

Installation of decorative soundproofing panels is carried out in two ways. Depending on the condition of the wall surface, the panel can be installed on special glue. According to the laying technology, this method has some similarities with the installation of ceramic tiles, the only thing is that the panels here have a large area.

@PaneliZvukoizolyatsii

The glue composition is applied to the wall surface with a special relief spatula. The tooth depth is six millimeters. The applied glue forms furrows, which, when pressed, are pressed in and forms a continuous layer.

After installing and pressing the panel against the wall, you need to hold the plate for literally two minutes so that the glue begins to set. The glue dries completely in a day.

If the surface of the wall is uneven, then in this case it is necessary to install decorative plates on the frame base. For the frame, a wooden beam or rail is used. Given the fact that the panels are soundproofing material, a large thickness structure is not necessary. It is enough to use thin rails to achieve a flat surface. Fixing the plates to the frame is carried out using a construction stapler and staples 10 mm in size. The distance between the fasteners should not exceed ten centimeters.

@PaneliZvukoizolyatsii

@PaneliZvukoizolyatsii

Modern soundproofing materials allow not only to provide an apartment from various types of noise, but also create a certain interior design. Thanks to the abundance of colors and textures, you can choose products for every taste and preference.

Using high-quality soundproofing in an apartment or house, you can relax in the evening from work and enjoy the peace. You will no longer hear neighbors swearing or a working puncher, reliable sound protection will create cozy and comfortable conditions.